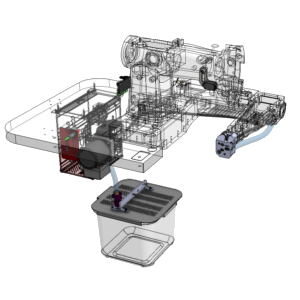

This machine is the result of AGM Special R&D team’s long-lasting effort. Equipped with a special full-oil gearbox system and special movable 3 roller pallet puller system, this machine will minimize the stitch defects usually seen in seam joint areas and during long operations.

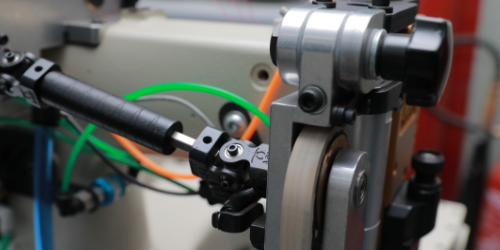

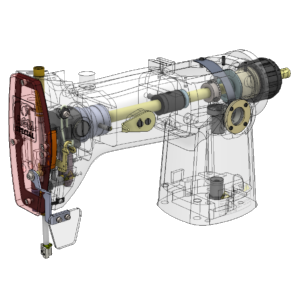

FULL OIL LUBRICATION SYSTEM GEARBOX

Full oil lubrication transmission system designed by AGM Special R&D department

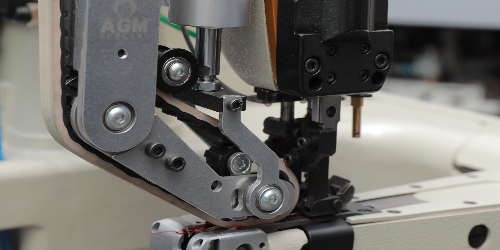

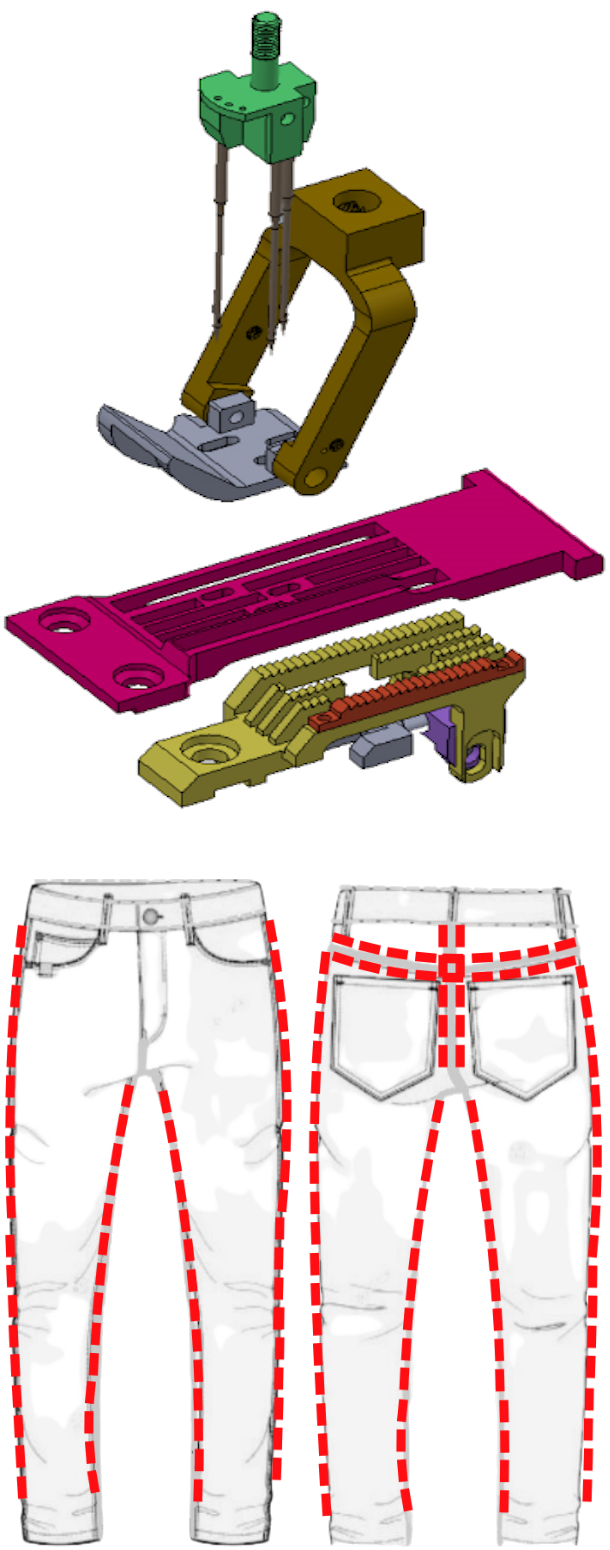

3 ROLLER PULLING DEVICE

Movable roller puller system that prevents overlapping the seem and puckering problems in joint areas

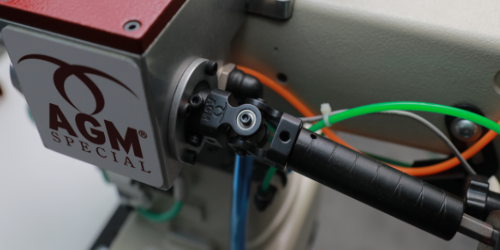

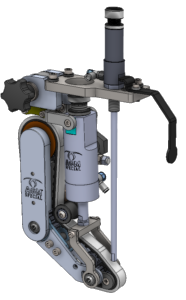

PRECISE THREAD CUTTING UNIT

ZD 1001 model automatic cutting unit designed by AGM Special

PERFECT FULL OIL LUBRICATION SYSTEM

Provides high performance without any oil leakage

TECNICAL FEATURES

Full oil lubrication gearbox transmission system

Movable roller puller system that prevents overlapping the seem and puckering problems in joint areas

ZD 1001 model long lasting thread cutting system designed by AGM Special

Direct drive servo electronic motor

Adjustable L type table and stand

Automatic foot lifter device

Extra strong needle cooling system

Special design guided pressure foot by AGM Special

Automatic double tension mechanism that prevents sharp chain stitch effects

3 needle chain stitch machine head with full oil lubrication system

OPTIONS

GUAGE SET OPTIONS

| Standard Gauge Set : 1/8″-1/8″ |

| Needle Distance : Minimum 1/8″ , Maximum 1/4″ |

| Needle No : Minimum 1 , Maximum 3 |

| Gauge Set Size : Minimum 1/8″ , Maximum 1/4″ |

| Optional Gauge Set: |

| 1/8″-1/8″ Slim Gauge (6.35mm , 3 needle) |

| 3/16″ Gauge Set (4.76mm , 2 needle) |

| 9/32″ Gauge Set (7.14 mm , 3 needle) |

| 5/32″ Gauge Set (4 mm , 2 needle) |

TECHNICAL SPECIFICATIONS

| Machine Head: | 3 needle chain stitch |

| Motor: | Direct drive servo electronic motor |

| Table and Stand: | Adjustable L type |

| Foot Lifter: | Automatic |

| Thread Cutting: | ZD 1001 model designed by AGM Special |

| Gearbox: | Full oil lubrication transmission system |

| Needle Cooling: | Extra strong needle cooling |

| Presser Foot: | Special designed guided pressure foot by AGM Special |

| Pulling Device: | Movable roller puller system that prevents overlapping the seem and puckering problems in joint areas |

| Tension: | Automatic double tension mechanism that prevents sharp chain stitch effects |

| Maximum Speed: | 5000 rpm |

| Voltage: | 220-240v 60Hz |

| Power: | 2400-2800w |

| Air Pressure: | 6 bar |

| Air Consumption: | 3 lt / min |

| Net Weight: | 98 kg |

| Gross Weight: | 111 kg |

| Dimensions: | 60x100x130 cm |