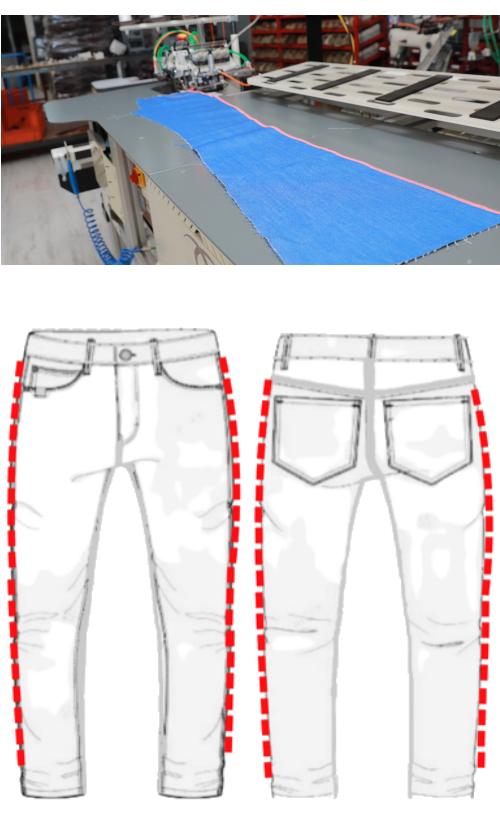

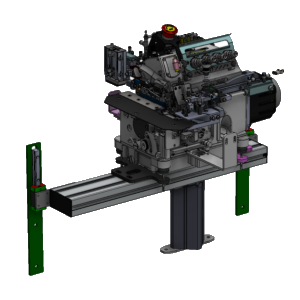

The paradigm-shifting innovation. The world’s first and only double-head serging automat. A real game changer resulted from many years of effort by Agm Special engineers. Innovative and practical, this serging machine can sew simultaneously both right and left trouser panels. The KLR 400-T2 is economically viable because it reduces by half the number of operators previously required for the this type operation.

UNIQUE DESIGN

Unique design that allows left and right two panels to be feeding from top to bottom at the same time

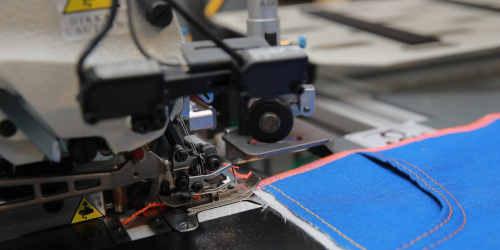

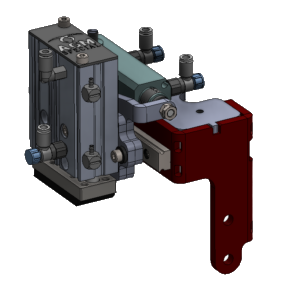

THE PRECISE THREAD CUTTING UNIT

The precise thread-cutting unit (that can cut the threads at the beginning and at the end of the process) with a double knife developed by a professional AGM Special R&D team

SPECIALLY DESIGN FOR JEANS

Specially designed for jeans fabric 4-thread left hand and 4-thread standard overlock machine head

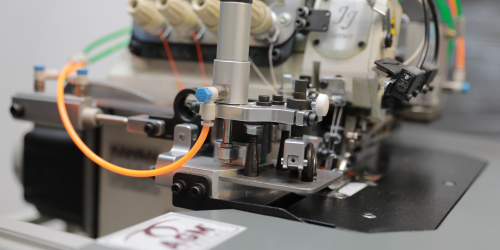

NEW DESIGNED ADJUSTABLE ACCURATE ZYPPY UNIT

New designed adjustable accurate zyppy unit that moves left- right and up-down according to different kinds of fabrics(light to heavy fabrics included full lycra and power stretches)

TECHNICAL FEATURES

Unique design that allows left and right two panels of the jeans trousers to be feeding from top to bottom at the same time

The precise thread-cutting unit (that can cut the threads at the beginning and at the end of the process) with a double knife developed by a professional AGM Special R&D team

New designed adjustable accurate zyppy unit that moves left- right and up-down according to different kinds of fabrics(light to heavy fabrics included full lycra and power stretches)

All kinds of deeply curved forms and straight forms of the panels can be surging precisely through the new fabric edge guide designed by AGM Special R&D experts

New designed stacker unit adjustable towards up and down for different lengths of panels

Very easy-to-use touch screen with Turkish and English languages option

The new automatic double-tension system enables automatically the tension while stitching and tension while empty chain stitch separately

OPTIONS

GUAGE SET OPTIONS

| Standard Guage Set : |

| Needle Distance : 3 mm |

| Threads No : 4 threads |

| Guage Set Size : 9 mm |

| Optional Gauge Sets : |

| Threads No : 3 threads |

| Needle Distance : 2-3 mm |

| Serging Width : 3 mm – 9 mm |

| Threads No : 4 threads |

| Needle Distance : 2-3 mm |

| Serging Width : 5.5 mm – 9 mm |

TECHNICAL SPECITICATIONS

| Thread Cutting: | Double knife developed by AGM Special |

| Machine Head: | 4 thread overlock |

| Motor: | Direct drive servo electronic motor |

| Zyppy Unit: | Adjustable up-down , left-right designed by AGM Special |

| Stacker Unit: | Adjustable up-down |

| Fabric Edge Guide: | Suitable for deeply curved forms of the panels |

| Tension Mechanism: | Double tension system enables automaticly stictching and empty chain stitch seperately |

| Presser Foot: | Special designed guided pressure foot by AGM Special |

| Touch Screen: | Easy to use touch screen with Turkish and English languages option |

| Voltage: | 220-240v 60Hz |

| Power: | 4800-5600w |

| Air Pressure: | 6 bar |

| Air Consumption: | 8 lt / min |

| Daily Capacity: | 6000 panels/8 hours |

| Net Weight: | 250 kg |

| Gross Weight: | 300 kg |

| Dimensions: | 200x120x160 cm |